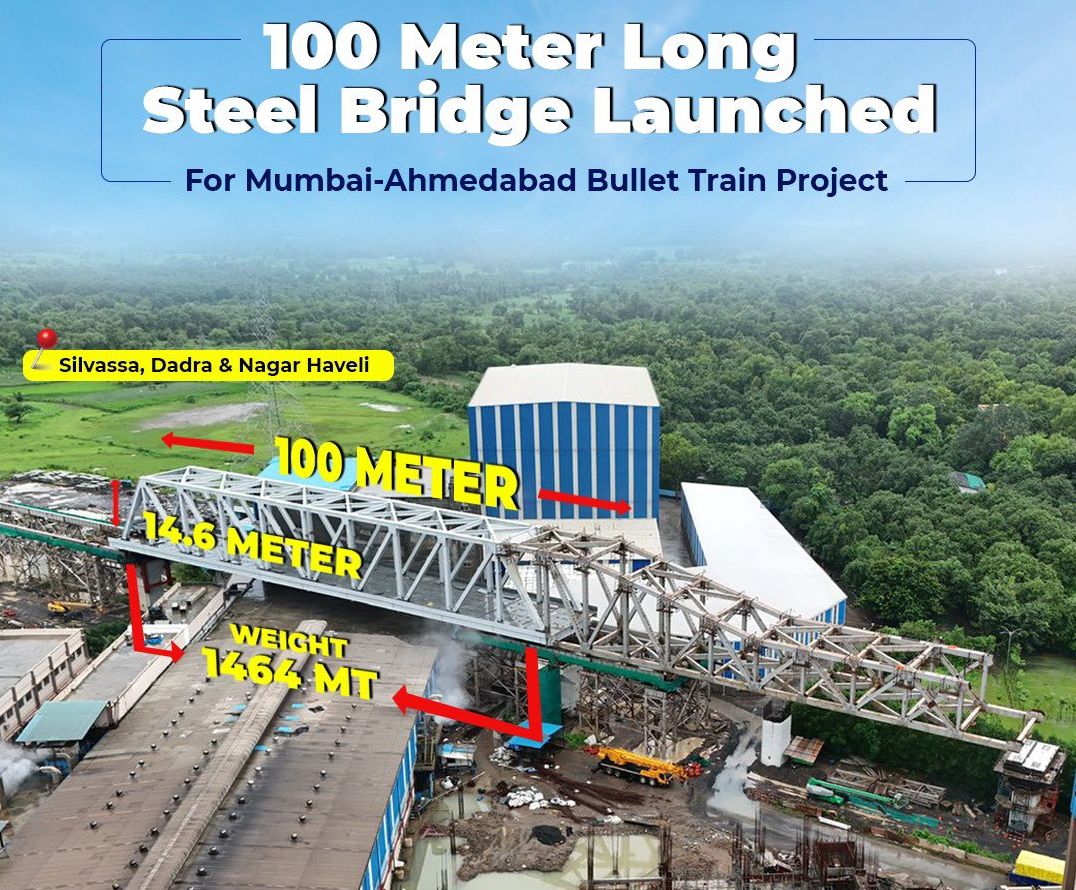

New Delhi, Aug 26, ‘Make in India’ 100 m long Steel Bridge Launches in Silvassa, Dadra & Nagar Haveli for Bullet Train Project. According to a press release issued by National High Speed Rail Corporation Limited (NHSRCL) here today, Another steel bridge of 100 m length has been launched for the Mumbai-Ahmedabad Bullet Train Project near Silvassa in Dadra & Nagar Haveli.

This 1464 MT of steel bridge of 14.6 m in height and 14.3 m in width has been fabricated at the workshop in Trichy, Tamil Nadu and was transported on trailers to the site for installation.

A temporary launching nose spanning 84 meters and weighing 600 MT was connected with the main bridge for launching, to avoid any intermediate support. Additional temporary members were also installed to strengthen the bridge during launching.

Total of 27,500 nos. of HSFG (High-strength friction grip) bolts were utilised to connect the components of launching nose and approximately 55,250 nos. of Tor-Shear Type High Strength (TTHS) bolts with C5 system painting and elastomeric bearings, were utilized for the main bridge

The steel bridge along with launching nose were assembled near the site at a height of 14.5 m from the ground on temporary trestles and was pulled with automatic mechanism of 2 number of semi-automatic jacks, each of capacity of 250 ton using mac-alloy bars.

The Bullet Train project is being executed meticulously, maintaining the utmost standards of safety and engineering excellence. Leveraging Japanese expertise, India is increasingly utilizing its own technical and material resources to build infrastructure under the “Make in India” initiative. The steel bridge for the Bullet Train Project is a major example of this effort.

This is the fourth out of the 28 steel bridges, completed for the Bullet Train corridor.New Delhi, Aug 26, ‘Make in India’ 100 m long Steel Bridge Launches in Silvassa, Dadra & Nagar Haveli for Bullet Train Project.

As stated here today by the Company Another steel bridge of 100 m length has been launched for the Mumbai-Ahmedabad Bullet Train Project near Silvassa in Dadra & Nagar Haveli.

This 1464 MT of steel bridge of 14.6 m in height and 14.3 m in width has been fabricated at the workshop in Trichy, Tamil Nadu and was transported on trailers to the site for installation.

A temporary launching nose spanning 84 meters and weighing 600 MT was connected with the main bridge for launching, to avoid any intermediate support. Additional temporary members were also installed to strengthen the bridge during launching.

Total of 27,500 nos. of HSFG (High-strength friction grip) bolts were utilised to connect the components of launching nose and approximately 55,250 nos. of Tor-Shear Type High Strength (TTHS) bolts with C5 system painting and elastomeric bearings, were utilized for the main bridge

The steel bridge along with launching nose were assembled near the site at a height of 14.5 m from the ground on temporary trestles and was pulled with automatic mechanism of 2 number of semi-automatic jacks, each of capacity of 250 ton using mac-alloy bars.

The Bullet Train project is being executed meticulously, maintaining the utmost standards of safety and engineering excellence. Leveraging Japanese expertise, India is increasingly utilizing its own technical and material resources to build infrastructure under the “Make in India” initiative. The steel bridge for the Bullet Train Project is a major example of this effort.

This is the fourth out of the 28 steel bridges, completed for the Bullet Train corridor.

New Delhi, Aug 26, ‘Make in India’ 100 m long Steel Bridge Launches in Silvassa, Dadra & Nagar Haveli for Bullet Train Project.

As stated here today by the Company Another steel bridge of 100 m length has been launched for the Mumbai-Ahmedabad Bullet Train Project near Silvassa in Dadra & Nagar Haveli.

This 1464 MT of steel bridge of 14.6 m in height and 14.3 m in width has been fabricated at the workshop in Trichy, Tamil Nadu and was transported on trailers to the site for installation.

A temporary launching nose spanning 84 meters and weighing 600 MT was connected with the main bridge for launching, to avoid any intermediate support. Additional temporary members were also installed to strengthen the bridge during launching.

Total of 27,500 nos. of HSFG (High-strength friction grip) bolts were utilised to connect the components of launching nose and approximately 55,250 nos. of Tor-Shear Type High Strength (TTHS) bolts with C5 system painting and elastomeric bearings, were utilized for the main bridge

The steel bridge along with launching nose were assembled near the site at a height of 14.5 m from the ground on temporary trestles and was pulled with automatic mechanism of 2 number of semi-automatic jacks, each of capacity of 250 ton using mac-alloy bars.

The Bullet Train project is being executed meticulously, maintaining the utmost standards of safety and engineering excellence. Leveraging Japanese expertise, India is increasingly utilizing its own technical and material resources to build infrastructure under the “Make in India” initiative. The steel bridge for the Bullet Train Project is a major example of this effort.

This is the fourth out of the 28 steel bridges, completed for the Bullet Train corridor.